Digital Twin Technology: Revolutionize Future of Industries

- Description

- Curriculum

- FAQ

- Reviews

A warm welcome to the Digital Twin Technology: Revolutionize Future of Industries course by Uplatz.

Digital Twin Technology creates a virtual representation of a physical object, process, or system. It enables real-time monitoring, simulation, and analysis of the physical entity through its digital counterpart, helping organizations optimize operations, predict outcomes, and improve efficiency.

How Digital Twin Works

-

Physical Entity: A real-world asset or system (e.g., a machine, building, or process).

-

Sensors: Data is collected from the physical entity through IoT devices or other monitoring systems.

-

Digital Model: A digital replica is created using advanced modeling, often leveraging technologies like machine learning, AI, and data analytics.

-

Data Integration: Real-time data is fed into the digital twin, ensuring it remains an accurate representation of the physical entity.

-

Simulation and Analysis: The twin can simulate scenarios, predict outcomes, and provide insights for decision-making.

Applications of Digital Twin Technology

-

Manufacturing

-

Optimize production lines.

-

Predict equipment failure and schedule maintenance.

-

Enhance product design by testing prototypes virtually.

-

-

Healthcare

-

Model patient-specific treatment plans.

-

Monitor wearable devices and simulate health outcomes.

-

-

Smart Cities

-

Monitor urban infrastructure (e.g., bridges, roads, and utilities).

-

Manage traffic flows and energy usage.

-

-

Automotive

-

Enhance vehicle design and testing.

-

Monitor fleet performance in real-time.

-

-

Energy and Utilities

-

Optimize energy grid management.

-

Simulate energy usage patterns to predict and meet demand.

-

-

Aerospace

-

Predict aircraft maintenance needs.

-

Simulate mission scenarios and improve operational efficiency.

-

Key Benefits

-

Predictive Maintenance: Anticipates failures before they happen, reducing downtime and repair costs.

-

Cost Optimization: Reduces the need for physical prototypes or frequent manual inspections.

-

Improved Efficiency: Provides insights to streamline operations and optimize performance.

-

Real-time Monitoring: Enables continuous oversight of physical assets and systems.

-

Enhanced Decision-Making: Offers data-driven insights for planning and innovation.

The technologies that power the creation and management of digital twins include a combination of hardware, software, and methodologies. These technologies collectively enable the robust creation, monitoring, and management of digital twins across industries. Some of the key ones involved are:

1. Internet of Things (IoT)

-

Sensors and Actuators: Collect real-time data from physical systems.

-

IoT Platforms: Manage data exchange between devices and digital twins (e.g., AWS IoT, Azure IoT Hub).

2. Data Integration and Management

-

Big Data Platforms: Process and analyze large volumes of data (e.g., Hadoop, Apache Spark).

-

ETL Tools: Extract, transform, and load data for synchronization.

-

Data Lakes and Warehouses: Centralized data storage for scalability and analytics.

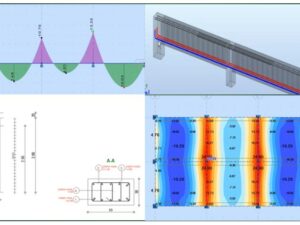

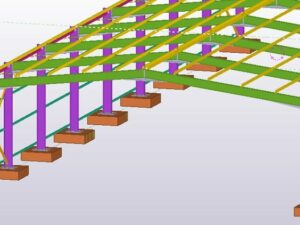

3. Simulation and Modeling

-

3D Modeling Tools: Create virtual representations of physical objects (e.g., CAD tools like AutoCAD, SolidWorks).

-

Physics Engines: Simulate real-world physics (e.g., Unity, Ansys).

-

Digital Thread Systems: Ensure seamless integration across lifecycle stages.

4. Artificial Intelligence (AI) and Machine Learning (ML)

-

AI Algorithms: Analyze patterns, optimize processes, and predict outcomes.

-

ML Models: Continuously improve performance based on data feedback loops.

-

Natural Language Processing (NLP): Enables interactions with digital twins using conversational interfaces.

5. Cloud and Edge Computing

-

Cloud Platforms: Provide the scalability and computational power for digital twins (e.g., AWS, Azure, Google Cloud).

-

Edge Computing: Processes data closer to the physical entity for faster response times (e.g., Cisco Edge, HPE Edgeline).

6. Connectivity and Networking

-

5G Networks: Enable high-speed, low-latency data transfer between physical and digital systems.

-

Protocols: MQTT, OPC-UA, and HTTP/HTTPS for secure data communication.

7. Analytics and Visualization Tools

-

Business Intelligence Tools: Analyze and visualize data from digital twins (e.g., Power BI, Tableau).

-

AR/VR Tools: Visualize and interact with digital twins in immersive environments (e.g., Microsoft HoloLens, Oculus).

8. Cybersecurity

-

Identity and Access Management (IAM): Protect access to digital twin environments.

-

Encryption Tools: Secure data during transmission and storage.

-

Threat Detection Systems: Monitor for vulnerabilities in IoT and digital ecosystems.

9. Integration Platforms

-

APIs and SDKs: Facilitate interoperability between systems (e.g., REST APIs, software development kits).

-

Enterprise Systems: Integrate with ERP, PLM, and CRM for business-level insights.

10. Standards and Protocols

-

Digital Twin Standards: Defined by organizations like ISO, IEEE, and Digital Twin Consortium.

-

Interoperability Protocols: Ensure compatibility across platforms and industries.

Digital Twin Technology: Revolutionize Future of Industries – Course Curriculum

-

Digital Twins – part 1

-

Digital Twins – part 2

-

Digital Twins – part 3

-

Digital Twins – part 4

-

Digital Twins – part 5

-

Digital Twins – part 6

-

Digital Twins – part 7

-

Digital Twins – part 8

-

Digital Twins – part 9

-

Digital Twins – part 10

-

Building Industrial Digital Twins – part 1

-

Building Industrial Digital Twins – part 2

-

Building Industrial Digital Twins – part 3

-

Building Industrial Digital Twins – part 4

-

Building Industrial Digital Twins – part 5

-

Building Industrial Digital Twins – part 6

-

Building Industrial Digital Twins – part 7

-

Building Industrial Digital Twins – part 8

-

The Engineering of Digital Twins – part 1

-

The Engineering of Digital Twins – part 2

-

The Engineering of Digital Twins – part 3

-

The Engineering of Digital Twins – part 4

-

The Engineering of Digital Twins – part 5

-

The Engineering of Digital Twins – part 6

-

The Engineering of Digital Twins – part 7

-

The Engineering of Digital Twins – part 8

-

The Engineering of Digital Twins – part 9

-

The Engineering of Digital Twins – part 10

-

The Engineering of Digital Twins – part 11

-

The Engineering of Digital Twins – part 12

-

The Engineering of Digital Twins – part 13

-

The Engineering of Digital Twins – part 14

-

The Engineering of Digital Twins – part 15

-

The Engineering of Digital Twins – part 16

-

The Engineering of Digital Twins – part 17

-

The Engineering of Digital Twins – part 18

-

The Engineering of Digital Twins – part 19

-

Digital Twin Technology – part 1

-

Digital Twin Technology – part 2

-

Digital Twin Technology – part 3

-

Digital Twin Technology – part 4

-

Digital Twin Technology – part 5

-

Digital Twin Technology – part 6

-

Digital Twin Technology – part 7

-

Digital Twin Technology – part 8

-

Digital Twin Technology – part 9

-

Digital Twin Technology – part 10

-

Digital Twin Technology – part 11

-

Digital Twin Technology – part 12

-

Digital Twin Technology – part 13

-

Digital Twin Technology – part 14

-

Digital Twin Technology – part 15

-

Digital Twin Technology – part 16

-

Digital Twin Technology – part 17

-

Digital Twin Technology – part 18

-

Digital Twin Technology – part 19

-

Digital Twin Technology – part 20

-

Digital Twin Technology – part 21

-

Digital Twin Technology – part 22

-

Digital Twin Technology – part 23

-

Digital Twin Technology – part 24

-

Digital Twin Technology – part 25

-

Digital Twin Technology – part 26

-

Digital Twin Technology – part 27

-

Digital Twin Technology – part 28

-

Digital Twin Technology – part 29

-

Digital Twin Technology – part 30

-

Digital Twin Technology – part 31

-

Digital Twin Technology – part 32

-

Digital Twin Technology – part 33

-

Digital Twin Technology – part 34

-

Digital Twin Technology – part 35

-

Digital Twin Technology – part 36

-

Digital Twin Technology – part 37

-

Digital Twin Technology – part 38

-

Digital Twin Technology – part 39

-

Digital Twin Technology – part 40

-

Digital Twin Technology – part 41

-

Digital Twin Technology – part 42

-

Digital Twin Technology – part 43

-

Digital Twin Technology – part 44

-

Digital Twin Technology – part 45

-

Digital Twin Technology – part 46

-

11Part 1 - Building Industrial Digital Twins

-

12Part 2 - Building Industrial Digital Twins

-

13Part 3 - Building Industrial Digital Twins

-

14Part 4 - Building Industrial Digital Twins

-

15Part 5 - Building Industrial Digital Twins

-

16Part 6 - Building Industrial Digital Twins

-

17Part 7 - Building Industrial Digital Twins

-

18Part 8 - Building Industrial Digital Twins

-

19Part 1 - The Engineering of Digital Twins

-

20Part 2 - The Engineering of Digital Twins

-

21Part 3 - The Engineering of Digital Twins

-

22Part 4 - The Engineering of Digital Twins

-

23Part 5 - The Engineering of Digital Twins

-

24Part 6 - The Engineering of Digital Twins

-

25Part 7 - The Engineering of Digital Twins

-

26Part 8 - The Engineering of Digital Twins

-

27Part 9 - The Engineering of Digital Twins

-

28Part 10 - The Engineering of Digital Twins

-

29Part 11 - The Engineering of Digital Twins

-

30Part 12 - The Engineering of Digital Twins

-

31Part 13 - The Engineering of Digital Twins

-

32Part 14 - The Engineering of Digital Twins

-

33Part 15 - The Engineering of Digital Twins

-

34Part 16 - The Engineering of Digital Twins

-

35Part 17 - The Engineering of Digital Twins

-

36Part 18 - The Engineering of Digital Twins

-

37Part 19 - The Engineering of Digital Twins

-

38Part 1 - Digital Twin Technology

-

39Part 2 - Digital Twin Technology

-

40Part 3 - Digital Twin Technology

-

41Part 4 - Digital Twin Technology

-

42Part 5 - Digital Twin Technology

-

43Part 6 - Digital Twin Technology

-

44Part 7 - Digital Twin Technology

-

45Part 8 - Digital Twin Technology

-

46Part 9 - Digital Twin Technology

-

47Part 10 - Digital Twin Technology

-

48Part 11 - Digital Twin Technology

-

49Part 12 - Digital Twin Technology

-

50Part 13 - Digital Twin Technology

-

51Part 14 - Digital Twin Technology

-

52Part 15 - Digital Twin Technology

-

53Part 16 - Digital Twin Technology

-

54Part 17 - Digital Twin Technology

-

55Part 18 - Digital Twin Technology

-

56Part 19 - Digital Twin Technology

-

57Part 20 - Digital Twin Technology

-

58Part 21 - Digital Twin Technology

-

59Part 22 - Digital Twin Technology

-

60Part 23 - Digital Twin Technology

-

61Part 24 - Digital Twin Technology

-

62Part 25 - Digital Twin Technology

-

63Part 26 - Digital Twin Technology

-

64Part 27 - Digital Twin Technology

-

65Part 28 - Digital Twin Technology

-

66Part 29 - Digital Twin Technology

-

67Part 30 - Digital Twin Technology

-

68Part 31 - Digital Twin Technology

-

69Part 32 - Digital Twin Technology

-

70Part 33 - Digital Twin Technology

-

71Part 34 - Digital Twin Technology

-

72Part 35 - Digital Twin Technology

-

73Part 36 - Digital Twin Technology

-

74Part 37 - Digital Twin Technology

-

75Part 38 - Digital Twin Technology

-

76Part 39 - Digital Twin Technology

-

77Part 40 - Digital Twin Technology

-

78Part 41 - Digital Twin Technology

-

79Part 42 - Digital Twin Technology

-

80Part 43 - Digital Twin Technology

-

81Part 44 - Digital Twin Technology

-

82Part 45 - Digital Twin Technology

-

83Part 46 - Digital Twin Technology

Social Network